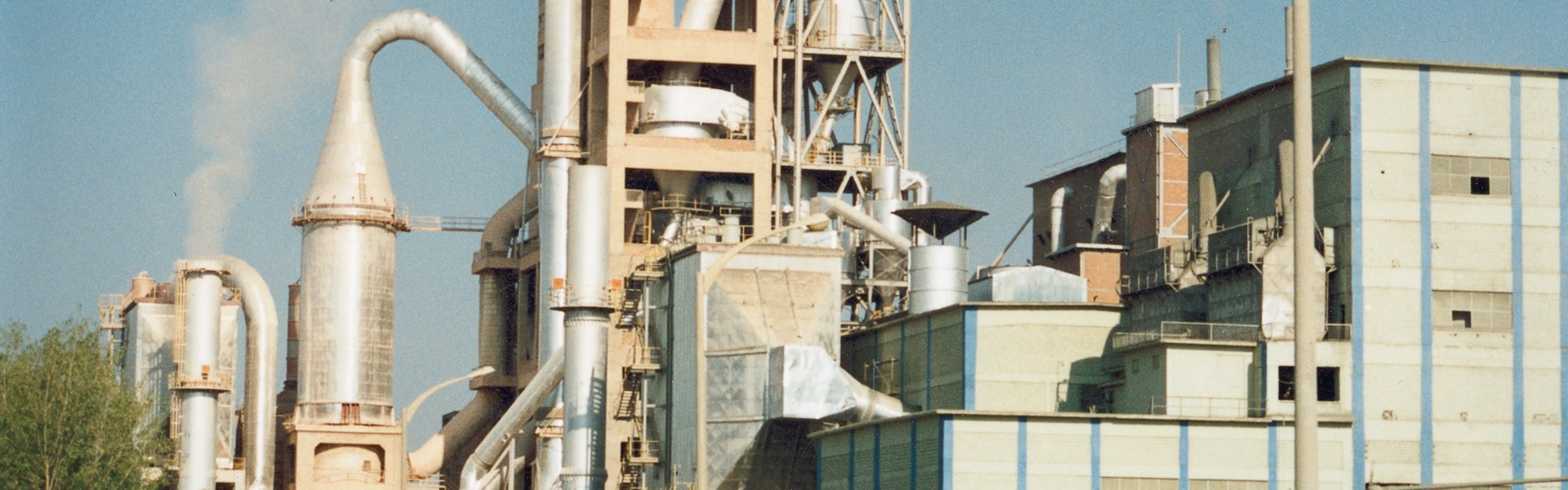

GAMA Industry executed construction, manufacturing and erection of Precalcination Unit.

Country: Turkey

GAMA Industry performed turnkey construction of the surface facilities for the copper/zinc beneficiation plant including partial basic and detail engineering and local equipment/material supply.

Turnkey civil construction of 35,000 m2 plant building for Mercedes-Benz bus assembly including auxiliary facilities is implemented.

GAMA Industry performed construction and erection of 1,500 ton/day capacity clinker production line as an extension to the existing factory, including crushing plant, raw materials grinding plant, preheater, kiln, dedusting unit and other associated systems including power supply system.

Construction of TES-IS Union Headquarters Building in Ankara with a total built-up construction area of 11,000 m2 on turnkey basis.

The building has 12 storeys, offices, guesthouse with 55 rooms, conference room for 600 person, exhibition hall, restaurant, garage, kitchen, laundry, air-conditioning centre, power generator room, 4 elevators and a service lift.

Design, supply and construction of a unique coal conveyor system, extending from Denis coal mines to Soma Power Plant was performed by GAMA in two phases. A 8,500 m long, single line, down hill belt conveyor system are constructed during the first phase whereas two 5,500 m long lines were installed during the second phase.

The conveyors have a capacity of 1,000 tons/hr each, a belt width of 1,000 mm and belt speed of 4.5 m/sec.

The Project was executed in technological partnership with KRUPP Industritechnik GmbH (Germany), a subcontractor to GAMA Industry.

The Soma-B Power Plant consisting of six coal-fired production units and auxiliary systems, was constructed on a turn-key basis and in three stages as follows:

Stage 1: Construction of 2×165 MW Units 1 & 2

Stage 2: Construction of 2×165 MW Units 3 & 4, including ash dam and hydraulic transport system

Stage 3: Construction of 2×165 MW Units 5 & 6

Flue gas desulphurization plant for 2×150 MW Cayirhan Thermal Power Plant Units I & II, consisting of 2 ea. 100 m high scrubbers, auxiliary systems and ancillary buildings.

GAMA Industry is responsible for detail design of all civil works, buildings, locally fabricated structural steel and equipment, complete electrical and instrumentation installation, and start-up and commissioning of the plant.

Supply and construction of 30 storey office building including computer center, 600 m2 conference hall, training center with dormitories, restaurant, kitchen and underground car park for 200 cars.

Total closed building area: 65,000 m2

Outdoor area: 40,000 m2

The Ayitli ash dam and hydraulic ash transport system is an integral part of the Soma-B Power Plant. The dam and the transport system were constructed by GAMA Industry under an annex to the second contract (Unit No. 3 and 4) of the Soma Power Plant contracts.

The project consists of ash fill dam (7,5 km from the plant), height: 85 m, crest length: 595 m, derivation tunnel (725 m long, 3 m dia.), redredging station, hydraulic ash transport system, 12 hydraulic ash transport pipelines (14 inches dia.).